In foodservice, simplicity sounds like a dream: one distributor, one contract, one invoice. Everything in one place, easy to manage.

But what happens when that one partner has a delay, a shortage, or a pricing shift? Suddenly, your entire operation is at the mercy of a single supply line.

That’s why the strongest operators don’t just chase simplicity; they build flexibility.

Every order, every contract, and every delivery connects back to your margins and your menu. And when your sourcing network is too narrow, your options shrink right along with it.

In today’s market, the operators who win are the ones who can pivot fast, not because they have one source for everything, but because they have visibility into everything.

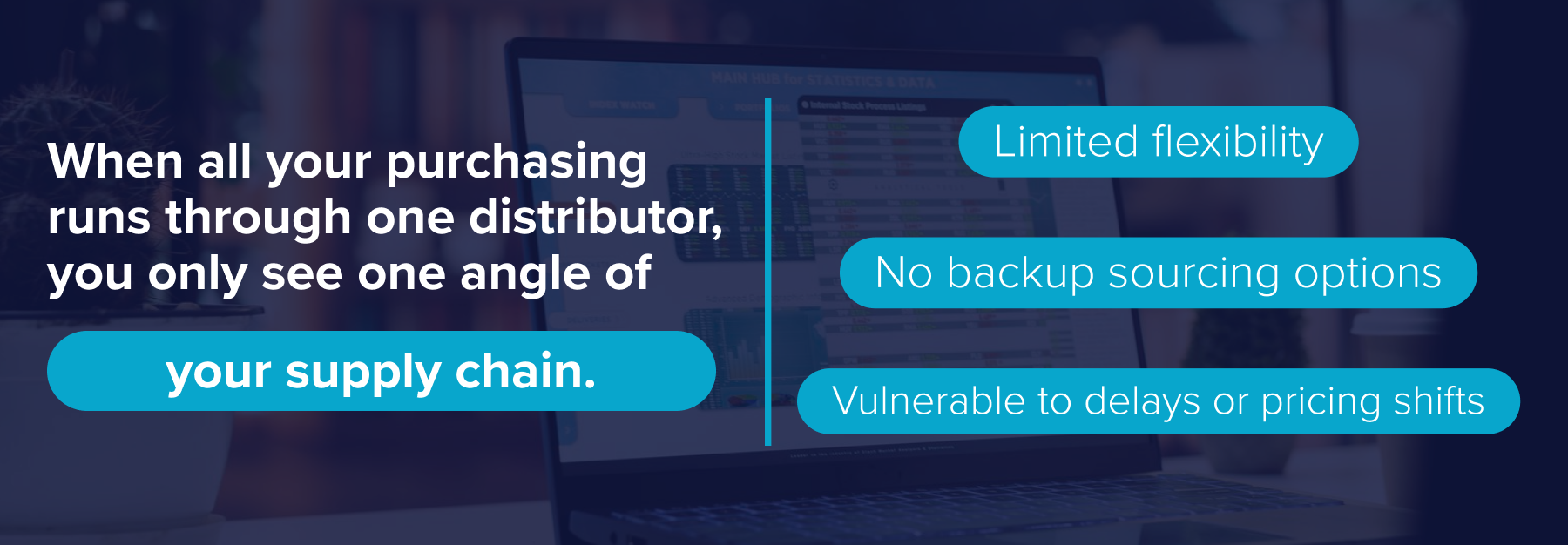

When Simplicity Becomes a Risk

Working with one distributor can feel efficient. The process looks cleaner, communication is faster, and it’s one less relationship to manage. But over time, that simplicity can become a bottleneck.

When all your products, pricing, and fulfillment depend on a single source, you lose leverage and the freedom to act when the unexpected hits.

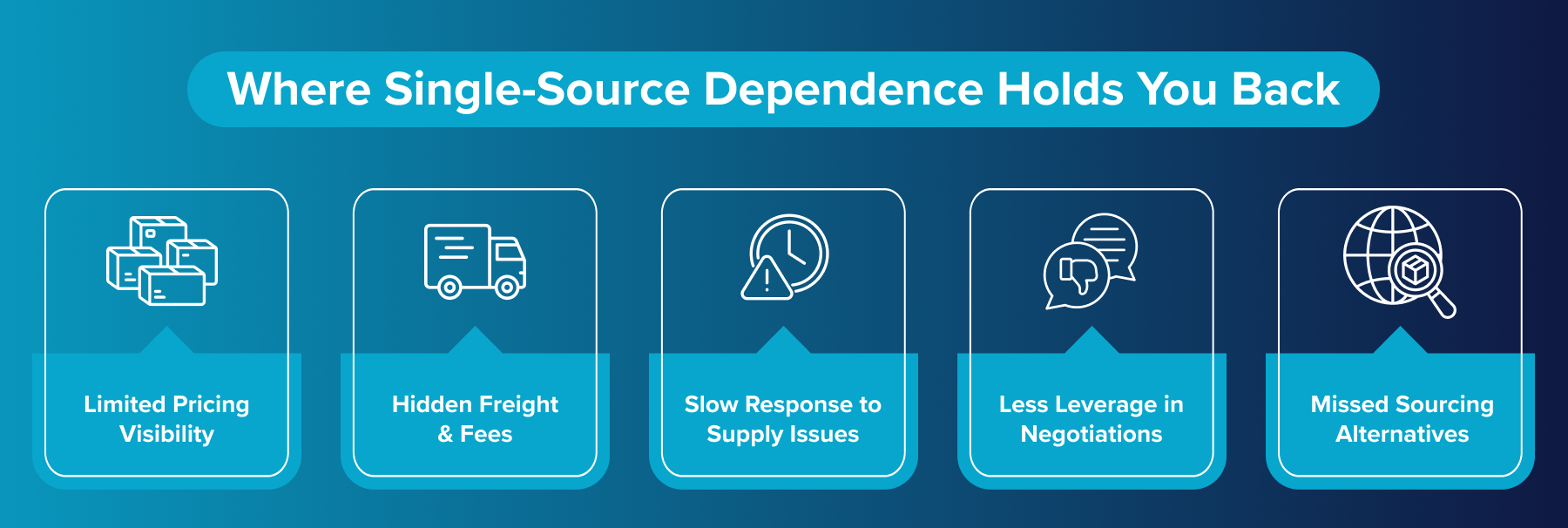

With multiple distributors, you gain more than options. You gain the ability to:

1. Substitute Products Quickly

If one distributor runs short, you have a backup ready no menu disruption or frantic last-minute sourcing.

2. Compare and Benchmark Pricing

You can see what’s competitive and what’s creeping up, using ArrowStream’s benchmarking tools to make every negotiation stronger.

3. Avoid Freight and Fee Surprise

Having visibility into multiple quotes means hidden costs stand out faster and stay under control.

4. Keep Quality Consistent

More supplier connections mean more choices to maintain standards when product availability shifts.

5. Build Resilience Into Your Supply Chain

Flexibility protects you from delays, disruptions, and dependency on a single point of failure.

The operators who thrive aren’t locked into one lane, they’ve built an adaptable network that can shift when the market does.

Building a Flexible Supply Network

True resilience starts with connection.

With ArrowStream’s Supplier Discovery and Sourcing tools, operators can easily research, compare, and collaborate with over 10,000 suppliers across the industry.

On average, 77% of your suppliers are already part of the ArrowStream network, making it easier to expand relationships without starting from scratch.

- A major QSR chain saved 18% on pickles after using Supplier Discovery to switch suppliers.

- Supplier Inquiry allows you to contact suppliers directly about product needs; no formal RFP is required.

- Supplier Sourcing lets you run sourcing events in a single day, compared to the traditional three-week process.

When those tools connect seamlessly with your price auditing and contract management in ArrowStream Central, sourcing smarter doesn’t add work; it saves it.

Visibility That Works for You

Visibility isn’t just seeing numbers on a screen. It’s knowing what they mean and what to do next.

That’s what ArrowStream delivers: clarity that helps you act fast, compare confidently, and plan ahead no matter how many distributors or SKUs you manage.

With one platform, operators can:

- Benchmark pricing across distributors and categories

- Track supplier performance in real time

- Identify gaps or opportunities in sourcing strategy

- Simplify collaboration across finance, operations, and purchasing teams

Because when everyone’s working from the same data, decisions get faster, negotiations get stronger, and supply chains get smarter.

The Power of Seeing (and Sourcing) the Whole Picture

In today’s foodservice landscape, visibility and flexibility go hand in hand. Relying on a single distributor might look efficient, but it limits your ability to adapt when markets shift or supply chains strain.

ArrowStream gives operators both the clarity to see what’s happening and the tools to act on it.

With a connected supplier network, real-time benchmarking, and sourcing tools that simplify complexity, ArrowStream helps you build a supply chain that’s transparent, resilient, and built to last.

Because in foodservice, the strongest operations aren’t the simplest, they’re the most flexible.