Inventory management is the heart of every restaurant chain’s supply chain and can be highly difficult to track. From manual processes to inaccurate data, it’s very easy to mismanage inventory across a supply chain network, resulting in unsatisfied customers and unnecessary financial losses. Conversely, optimizing this process can help supply chain teams gain higher visibility to manage consumer fluctuations, reduce food waste, increase profits, and maintain consistency across your brand.

Inventory management is also important in optimizing big-picture company objectives, such as improving stock value, quality, and customer satisfaction. Unfortunately, for supply chain staff who feel their inventory management is reactive and delayed, any inefficiency can greatly impact the long-term economic success and reputation of a business.

Why supply chain teams need a food inventory management system

Foodservice inventory management systems monitor all inventory moving throughout your supply chain from your suppliers and DCs to your restaurant locations.

Visibility into your supply chain is key to proper inventory management and optimizing profitability. This is because end-to-end visibility shows segments of the supply chain that can be made stronger and more efficient while highlighting all potential risks.

A centralized, tech-enabled system allows you to simultaneously restrict processes that are causing you to lose money, such as rogue buying off contract, while identifying new savings opportunities. Inventory management data enables teams to quickly prioritize and make decisions to mitigate risk, optimize profitability and protect your brand.

Hear from one of our customer, Megan Scherer, Senior Manager of Supply Chain at Shake Shack, on how her team uses ArrowStream’s Inventory Visibility solution to manage changes caused by the COVID-19 pandemic:

With precise visibility of product movement and risks, as well as where money, time, and staff are being allocated, digitizing the supply chain is an industry best practice that has become critical in our new environment. Reference the following 4 best practices when considering an inventory management system, and ensure you’re utilizing it to the fullest degree.

1. Access important risk mitigation data

An automated supply chain software solution computes important inventory calculations so you can put an end to human error, delayed management, and wasted time when resolving and mitigating risks.

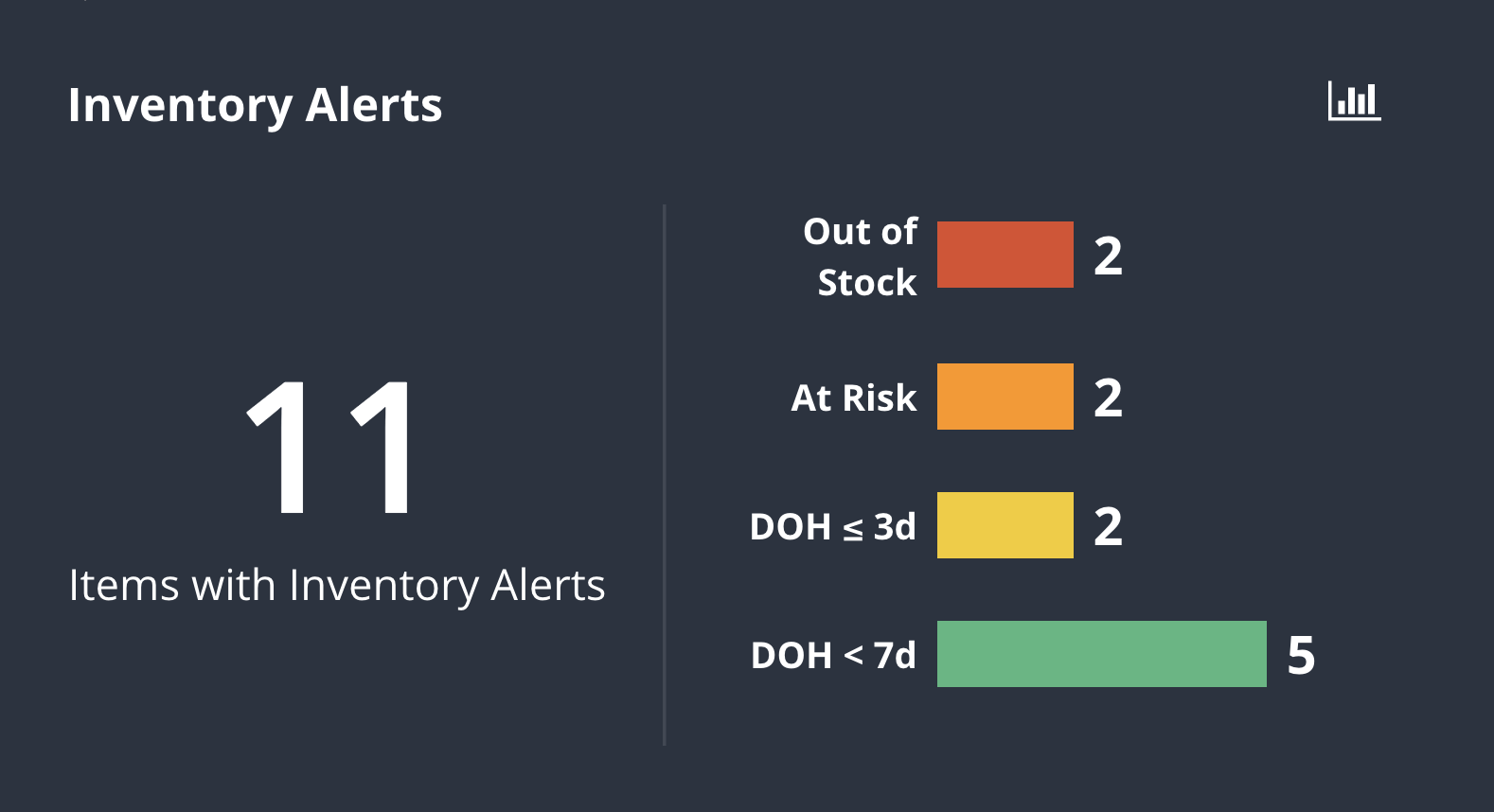

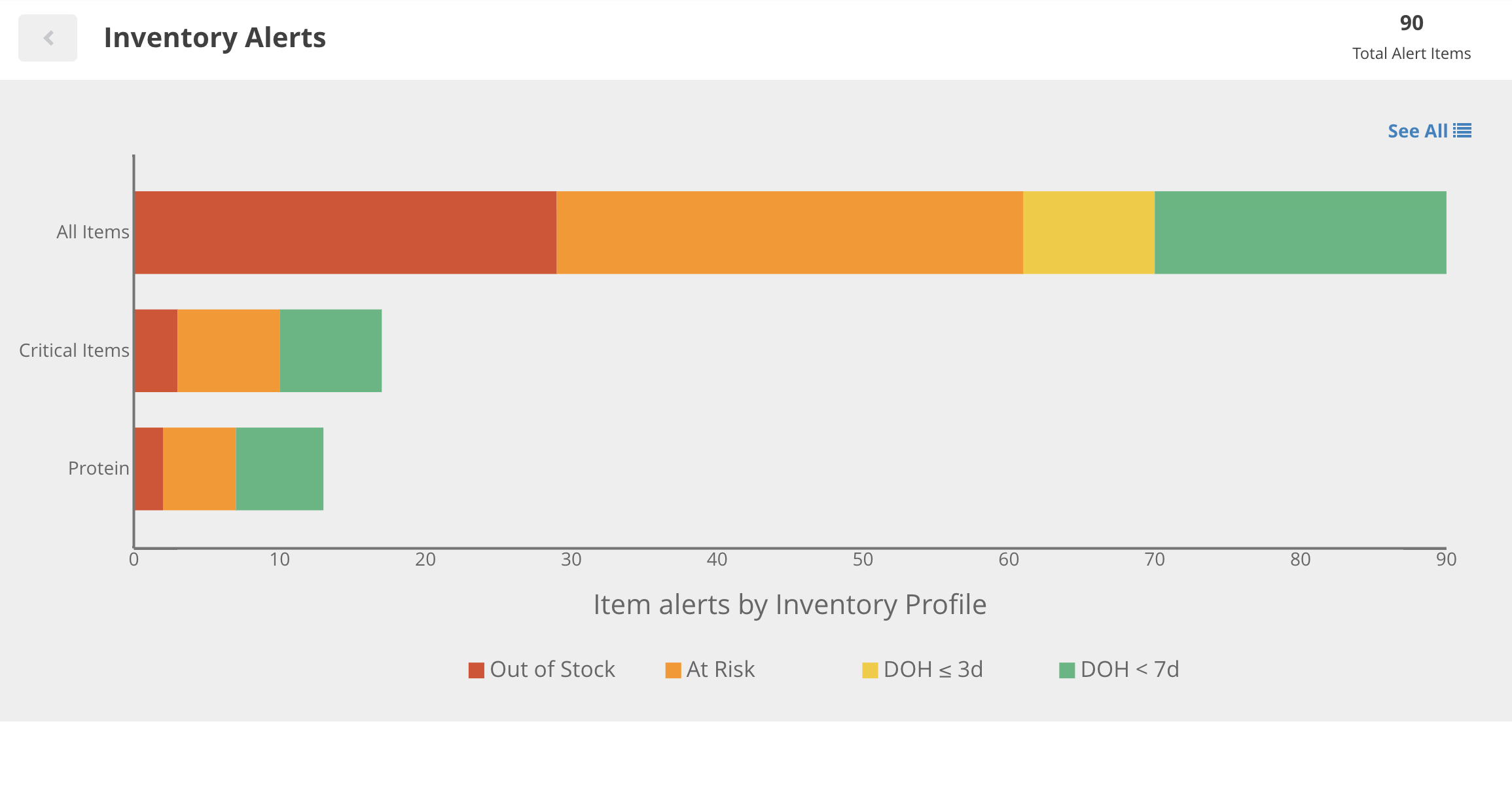

Real-time inventory calculations reduce the risks of stock-outs or shortages, outdated inventory, product substitution complications, and any product non-compliance. Automated alerts to potential risks can help supply chain teams prioritize their time and determine quickly what is a threat and what is not.

Accurately assess inventory risks with visibility into supply chain data, such as:

- Days of inventory on-hand

- Product runout tracking

- Visible inventory (and product substitution) movements

- Accurate inventory arrival time estimates

- Alerts on critical preselected inventory items

Leverage data and these calculated figures with personalized dashboard and reporting capabilities as well as possible data extraction for offline analysis. With these tools by your side, you can expertly manage your inventory supply while preventing shortages, streamlining product substitutions and reducing costs.

Performing a consistent risk mitigation strategy will ensure your customers are always satisfied with their favorite meals, a consistent customer experience, and high-quality products.

2. Promote perpetual inventory checking

Inventory management software offers continuous inventory checks with real-time data. This ensures that updates related to sourcing, inventory stock levels, sales, inventory arrival times, and more can be perpetually updated within one system. Designated employees can then consult data or take the necessary action in response to the incoming information.

Benefits include increased accuracy in advising inventory turnover, managing consumer and market fluctuations, scalable inventory management of expanding restaurant chain locations, and improved forecasting abilities for the following months and years.

How are these benefits made possible? Supply chain teams can easily manage inventory turnover with immediate access to inventory level data. Data centralization further garners scalable inventory visibility because you can track the activity of multiple locations within an intuitive, ‘1-click’ tile dashboard.

The constant inflow of foodservice supply chain data effortlessly visualizes patterns of corporate buying and consumer demand, revealing expert insights into fluctuating yearly consumer behaviors and habits. This reliable system allows forecasting to be personalized based on your restaurant chain, product, location, and consumers, making for more reliable current and future inventory management.

The constant inflow of foodservice supply chain data effortlessly visualizes patterns of corporate buying and consumer demand, revealing expert insights into fluctuating yearly consumer behaviors and habits. This reliable system allows forecasting to be personalized based on your restaurant chain, product, location, and consumers, making for more reliable current and future inventory management.

3. Consolidate suppliers & product mixes

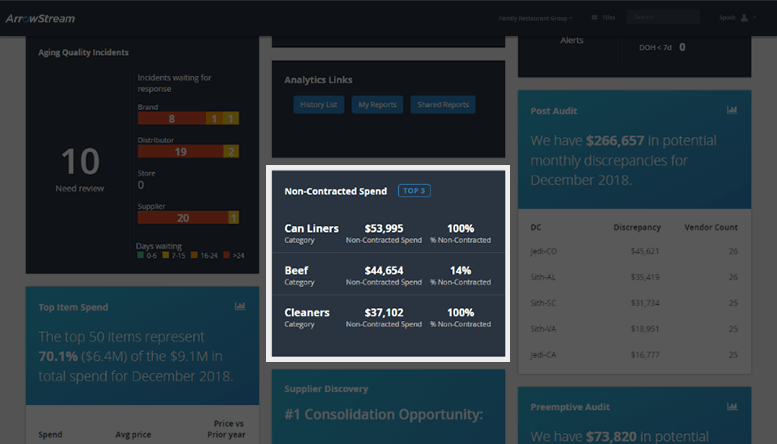

When it comes to inventory management, having fewer suppliers and multipurpose ingredients can be a good strategy. By having full visibility of inventory levels and product spend, you can identify opportunities to consolidate product sourcing under your best or new suppliers, which results in cost savings and improved quality control, making for a simpler, more reliable supply chain.

Inventory-focused supply chain software offers user-friendly dashboards and analytics to help supply chain teams understand spend records by product type and supplier, giving them better insights into their daily tasks and inventory level maintenance.

By increasing contracted spend under your favorite suppliers, you secure cost control, the best product quality possible, and a supplier partnership consisting of accountability, transparency, and trust.

Determining which suppliers to expand your inventory sourcing with can be difficult when using a manual system, however, software significantly helps this. It also promotes transparency and informs your purchasing team of suppliers who are doing great work with fairly calculated performance scores based on the metrics most important to your business.

Beyond this, increasing contract spend simultaneously reduces dreaded rogue purchasing, which can be as high as 3% of your contracted spend. The issue with this is that rogue purchases are typically 12% higher in cost compared to your predetermined, contracted items and can strain your budget.

Consolidating suppliers and increasing contracted spend plays a large part in inventory management because it can bring more focus and control to the starting segments of your inventory paths throughout the supply chain. This means inventory risks are reduced, and if one does occur, there is a much simpler process to fix it.

For times when you need to locate a new supplier partner, it’s best to find a technology partner with an extensive network to leverage. For instance, ArrowStream offers its restaurant chain customers access to a database of over 8,000 foodservice suppliers to source product from, encouraging a strong partner collaboration strategy.

4. Ensure broad adoption of your inventory management software to enhance collaboration

Promote the full adoption of your foodservice inventory management software among all staff and partners to consolidate internal and external operations. This means that data on product spend, inventory levels, and more remain updated, accurate and visible to all teams, ensuring a centralized data source of supply chain information that’s entered within the same software platform.

When foodservice organizations have all data within one single hub, software automation can verify data discrepancies and develop analytical insight based on all data sets.

All supply chain staff and partners can then consult a single source of data, offering an expansive view of company developments as well as a guided plan of action. Furthermore, intuitive dashboards conveniently showcase highly relevant data, making it easy for supply chain teams to develop actionable goals and initiatives.

Promoting that employees fully integrate their daily tasks with a centralized software system ensures the best return on investment and data control.

No matter your restaurant chain’s operational state or stage, ensuring all have access to transparent data within the supply chain allows operators to effectively prevent inventory risks, plus more.

BONUS BEST PRACTICE

5. Invest in inventory management system training

Data intelligence, automation, and red-flag alerts go a long way in providing top-notch inventory management. However, if information inputs are incorrect or non-existent, the system may reflect the inaccuracies if not caught in time.

To avoid this, rely on data-conscientious staff members to carry out foodservice inventory management best practices and train the rest of your staff for consistent company records. This way, all tiers and segments of the supply chain understand all inventory system categories and are accountable to contribute their own correct data.

In addition, ensure every user of your inventory software has a solid understanding of all feature capabilities so your supply chain operation doesn’t miss critical opportunities or threats. The best technology partners will offer strategic account management in addition to technical support and it’s in your organization’s best interest to take advantage of it.

This expansive company collaboration results in reliable inventory supply chain management where communication is streamlined, issues are avoided and goals are met.

Transform your inventory management strategy with technology upgrades

Begin using a personalized inventory management software system to view your supply chain network’s inventory in its entirety. Never be surprised by inventory issues with intelligent and centralized data. Talk to our subject matter experts to learn about modernizing to a digital supply chain.